|

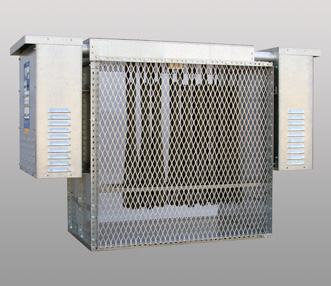

LBD-Series load banks utilize the radiator air outflow of a generator engine to cool the resistive load elements. The LBD can be adapted to fit varying site conditions and duct dimensions, making it ideal for after market retrofit. Pictured is a bolt-together LBD. Many options are available to suit individual requirements and simplify installation.

Applications

Reliability exercise and testing of standby generator sets.

Base load leveling to eliminate the deleterious effects of low load operation.

Automatic protection against generator reverse power and motoring of prime mover by power regenerated by inertial loads.

|

General

| • | The bolt-together LBD (50KW-400KW) has earned the UL Listing Mark. |

| • | Simplex LBD load banks can be used to satisfy the requirements of the National Fire Protection Association (NFPA) for emergency stand-by power systems. |

Load Elements

| • | The bolt-together LBD (50KW-400KW) utilizes the UL Recognized Simplex Powr-Rod element. |

| • | The weld-together LBD (400KW-1200KW) utilizes the UL Recognized Simplex Powr-Web element. |

System Controls

| • | Local or remote controls. |

| • | Control compartments thermally insulated from load elements. |

| • | Indicator lights: Normal Operation and Cooling Failure. |

Cooling

| • | Utilizes the air outflow of an engine radiator. |

Malfunction Protections

| • | Cooling failure sensors lock out load application. |

| • | Load Circuit Protection: branch circuit fuses. One set of fuses each 50KW branch. Fuses are current limiting type, 200,000 AIC, 600V, enabling safe use on large generating or UPS system. |

Load Control

| • | Branch circuit contactors each step or each 50KW circuit maximum. |

| • |

Contactors with enclosed silver surfaced contacts, 120V coils; electrically operated and electrically held. |

Connections

| • | Control Wiring: 105°C, color coded. |

| • | Power Wiring: 150°C XLP color-coded. |

| • | Cables connect to full rated copper bus bar with an oversized terminal junction box. |

Enclosure

| • | The bolt-together LBD (50KW-400KW) utilizes a galvanized steel construction. |

| • | The weld-together LBD (400KW-1200KW) enclosure is finish painted with a UL Listed process consisting of either a powder-coated finish or a liquid-coated finish consisting of an epoxy primer and a polyurethane finish. |

| • | Service access panels. |

| Capacity |

Bolt-together: 400KW

Weld-together: 1200KW |

| Load Type |

Resistive |

| Power Factor |

1.0 |

| Voltages |

All common 3-phase

60 and 50 Hz voltages:

60 Hertz: 208V, 220V, 240V, 416V, 440V, 450V, 460V, 480V, 575V, 600V

50 Hertz: 190V, 200V, 208V, 380V, 400V, 416V |

| Frequency |

50-60-400 Hz |

| Load Steps |

50KW resolution |

| Duty Cycle |

Continuous |

| Temperature |

Exhaust rise: RISE=KW x 3000 / CFM (Note: as airflow is not laminary, exhaust air temperatures are not equal at all points at the plane of air exhaust. Some parcels of air may reach approximately 575°F before mixing. |

| Airflow |

Radiator. |

| Control Power |

Internal, from load bus.

Load control circuits operate 120V via transformer. Control circuits are fused. |

| Dimensions |

Varies by capacities and options selected. |

| Weight |

Varies by capacities and options selected. |

System Controls

Instrumentation

Enclosure

| • | Outdoor configuration. |

| • | Mounting angles. |

| • | Mounting feet. |

| • | Anti-condensation heaters at 120V, 1ø, 240V 1ø, or any common 3ø voltage. |

Note: We are experts at building products that meet our customer's exact requirements. Contact Simplex if your job specifications require additional options or considerations.

|